Dr Piotr Kijanka, AGH University associate professor, Photo by Marianna Cielecka

Dr Piotr Kijanka, AGH University associate professor, participated in the development of a miniature sensor for constant monitoring of internal organs, developed by a team of researchers from the Massachusetts Institute of Technology (MIT) and the University of Southern California (USC). It may be applied among others in patients after kidney and liver transplants, allowing for early detection of symptoms of acute multiple-organ system failure and transplant rejection.

The device of a size of a post stamp adhered to the body was recently presented by the group of researchers in the prestigious Science Advances journal. With one of the techniques of medical imaging, namely ultrasound elastography, the device uses ultrasonic waves penetrating into the body as a probe. Organs subjected to impulses of a focused acoustic beam begin to gently vibrate and emit elastic transverse waves registered by the device. The technique takes advantage of the fact that pathological processes cause gradual changes in the mechanical properties of organs. Diseased organs subjected to an impulse of a focused acoustic beam vibrate differently from healthy organs, which translates into a change in the speed and profile of propagation of transverse waves. If they deviate from the reference values, this is a signal that something wrong is happening in the patient's body.

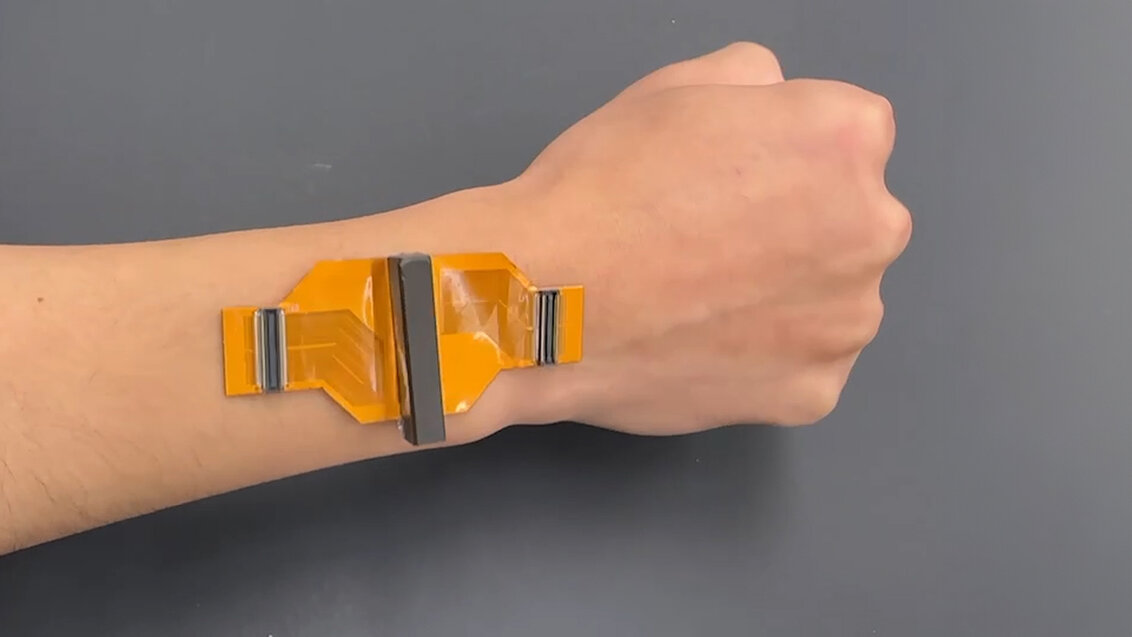

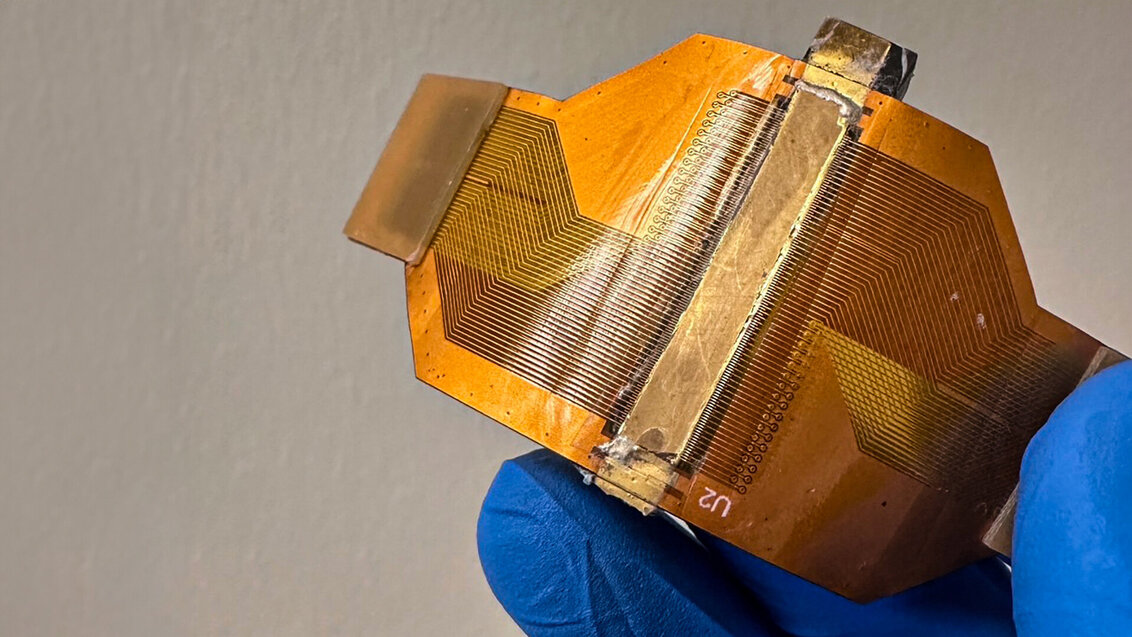

Ultrasound sticker developed at MIT, Photo provided by the researchers

At the device development stage, Dr Piotr Kijanka, professor at the Faculty of Mechanical Engineering and Robotics, was responsible for the numerical validation of wave processes taking place in tissues.

“Plenty of physical phenomena, such as the propagation of acoustic or elastic waves, may be described with the use of differential equations. The equations themselves have been known for a long time, however, in order to make any calculations, one has to perform numerical optimisation taking into account all boundary conditions,” the AGH University researcher explains. “The parameter ranges have been discussed in the literature and confirmed by a number of studies. Nevertheless, it is not the case that this issue did not require any further thought. Before I found the right numerical solutions, I had spent hours talking to my teammates about what the experiments would look like. It was key for me to learn as many details which require consideration in calculations as I possibly could. If I omitted some relevant aspects, it could mean that the obtained results would not have any basis in reality."

Small device with large capacity

The ultrasound elastography technique itself is not new in medicine, but the apparatus used for this purpose so far requires the use of a hand-held head, moved over the body of the examined patient. Such a solution does not allow for the continuous monitoring required, for example, by patients after kidney or liver transplant, in whom a change in the mechanical properties of the organ can herald its acute failure and the body's rejection of the transplant. Meanwhile, the device developed by engineers at MIT and USC allows more than 48 hours of uninterrupted operation and can detect signs of a pathological process within just six hours of their occurrence. Despite the miniaturisation, the developers managed to place 128 piezoelectric transducers on a length of 24 mm, which is equivalent to their number in the commercial heads in use today, which are 40 mm in size. The device is attached to the patient's skin using a special water- and polymer-based gel previously developed at MIT, which allows lossless transmission of sound impulses between the device and the patient's body. Another advantage of this device is that it can produce an acoustic radiation force impulse to induce transverse waves, which is usually not achievable with such a small device.

Ultrasound sticker developed at MIT, Photo provided by the researchers

So far, the effectiveness of the developed solution has been confirmed in tests on rats. The team is currently working to make the device usable by organ transplant patients in hospital transplant wards. Ultimately, the creators of the device would like it to be used by those in need at home, at the expense of a slight increase in size. As declared by Professor Kijanka, the transition from a rat model to a human model does not stand a problem from a numerical point of view.

“The tissues are very similar in terms of their mechanical properties. Only input parameters, such as those describing the stiffness and viscosity of the material, may need to be changed in value.

From mechanical to biomedical engineering

Professor Piotr Kijanka has been concerned with the topic of ultrasounds since the beginning of his scientific career, but initially his attention was focused on using them to detect damages in mechanical structures. The academic devoted his doctoral dissertation to this very issue. A breakthrough in his scientific resume was his two-year employment, starting in 2017, at the Mayo Clinic Hospital in Rochester, USA, where he was promoted to Assistant Professor of Radiology for his scientific achievements.

“Since I started working at the hospital, I have been able to translate all of my knowledge from mechanical engineering into biomedical engineering. I have also had the opportunity to learn a lot, as the access to research infrastructure was excellent. I have also participated in a number of clinical trials, so I have been able to personally experience what it is like. Since then, I have practically shifted all my energies and interests toward biomedical engineering,” Professor Kijanka said.

Pre-election meeting with a candidate for the position of rector

Pre-election meeting with a candidate for the position of rector  Agreement on cooperation with OPAL-RT

Agreement on cooperation with OPAL-RT  Krakow DIANA Accelerator consortium members with an agreement

Krakow DIANA Accelerator consortium members with an agreement  Meeting with the Consul General of Germany

Meeting with the Consul General of Germany  More Academic Sports Championships finals with medals for our students

More Academic Sports Championships finals with medals for our students  Launch of AGH University Student Construction Centre

Launch of AGH University Student Construction Centre  Bronze for our swimmers at Academic Championships

Bronze for our swimmers at Academic Championships  Smart mountains. AGH University scholar develops an intelligent mountain rescue aid system

Smart mountains. AGH University scholar develops an intelligent mountain rescue aid system